Energy Upgrades to Wastewater Treatment

Montpelier Water Resource Recovery Facility (from left) Nathan Wilson (Project Manager- ESG), Kurt Motyka (Deputy Public Works Director) and Christopher Cox (Chief Operator) next to the anaerobic digesters, spring 2021

In May 2021, Montpelier’s Water Resource Recovery Facility (WRRF) completed a major upgrade to reduce fossil fuel use at the plant as part of the City’s path towards its goal for municipal operations to be Net Zero by 2030.

This project has been in the works since the summer of 2018. When the City began planning for needed upgrades, it recognized an opportunity to significantly increase the amount of biogas produced by the WRRF by upgrading its anaerobic digesters and bringing in additional high strength organic waste from local food processors and haulers.

The initial cost estimate to complete all the Aging Infrastructure improvements was over $13 million. If undertaken as a standalone project, this would have increased the Sewer Fund’s debt service by over $500,000 a year, resulting in significant increases in sewer bills for Montpelier residents. By incorporating the Organics to Energy project into the Aging Infrastructure project, the City was able to lower operating costs and increase revenues from tipping fees through improved organic waste digestion and renewable biogas production. This additional revenue will offset the costs associated with the Aging Infrastructure project. Additional grant funds and low-interest loans from USDA Rural Development and the Vermont Department of Environmental Conservation also helped to offset the capital costs of the project. The combination of grant funds and below market rate interest is expected to save ratepayers in Montpelier and Berlin over $10 million in financing costs over the next 30 years. Montpelier’s Public Works Department was honored by the American Public Works Association for the Rural Communities Project of the Year/Environment for the recently completed Aging Infrastructure/Organics to Energy project.

This WRRF upgrade project added capacity for an additional 23,000 gallons per day of high strength organic waste (HSOW) to Montpelier’s facility. HSOW includes feedstocks in the form of dairy industry by-products, brewery and distillery waste, fats, oils and grease from restaurants and food products production, and de-icing agents from airports. Typically this type of waste is challenging to landfill or compost, and Montpelier provides a much needed service by accepting these types of waste at the WRRF. The Organics to Energy project processes and removes phosphorus from high strength wastes which would otherwise be either directly land applied or placed into commercial digesters whose digestate is land applied as fertilizer, contributing phosphorus to the water flowing into Lake Champlain and other waterways. The amount of phosphorus in treated water released by the facility continues to meet all state standards for pollution control.

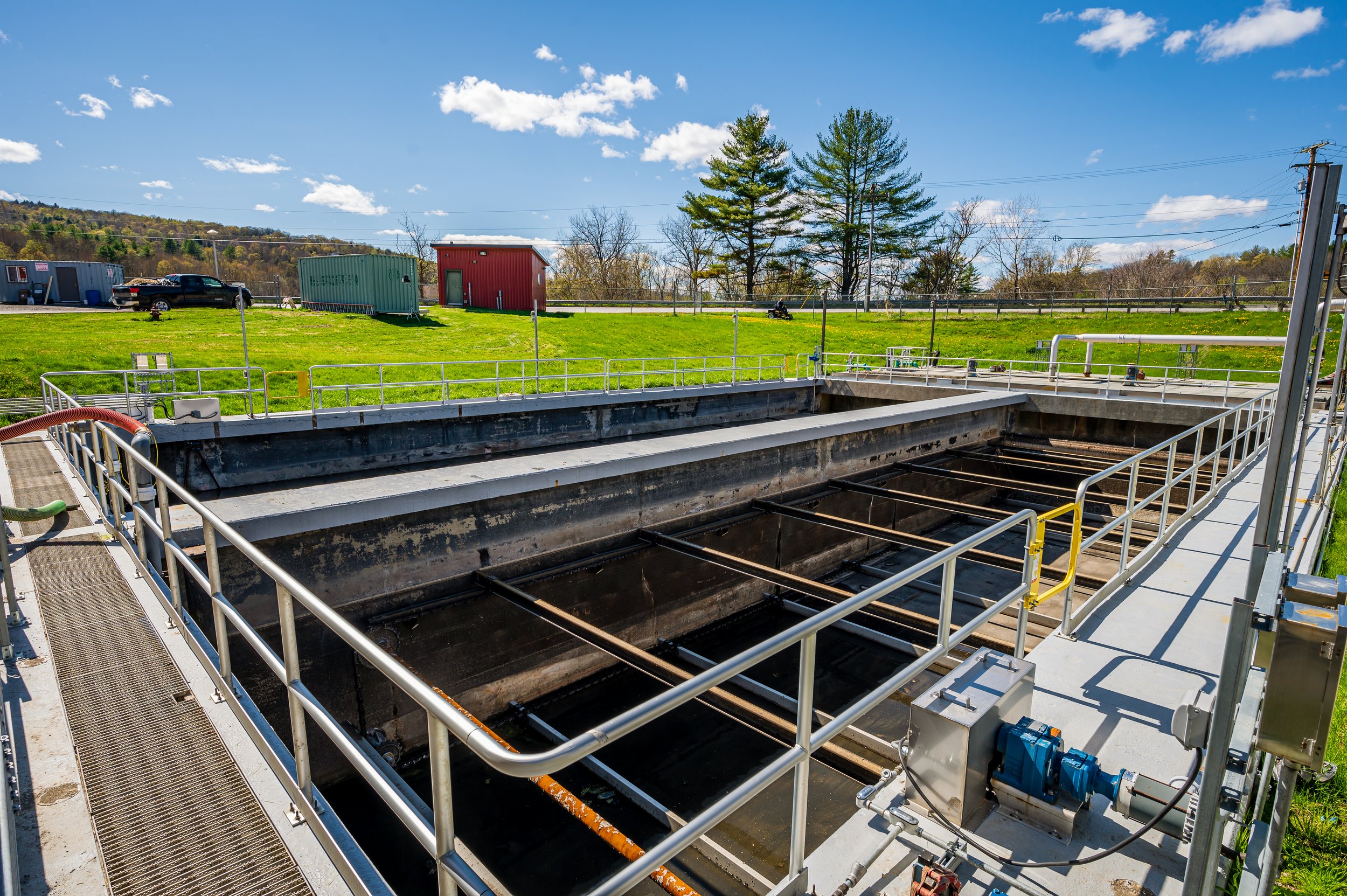

The ability to receive organic waste will provide a significant new stream of revenue for the City and provides a sustainable waste treatment alternative to the region’s organic waste haulers. Other improvements included an upgraded receiving station, solids dewatering and thickening, and new dual fuel boilers to run on biogas reducing energy costs. Additional upgrades included UV disinfection systems, replacement of the grit classifier, grit pumps and grit washer, replacement of primary clarifier internals, and upgrades to the SCADA system. The plant began receiving high strength organic waste (HSOW) in early 2021. Currently the plant has contracts with seven companies to bring HSOW to the plant.

The additional biogas produced from digesting the HSOW is used to heat the buildings at the WRRF and the digesters in the winter, reducing the WRRF’s fossil fuel use to nearly zero. A Phase 2 project to use excess biogas to dry the sludge into Class A biosolids is in the planning stages. The Phase 2 dryer project would significantly reduce the amount of wet sludge that is shipped to the Coventry landfill, and utilize excess biogas that currently is being flared.

In addition to reducing fossil fuel use by switching to biogas for heating, the WRRF has also implemented a series of electricity saving projects, installed a 62.2 kW solar array on the roof, and purchased additional solar credits from an offsite solar farm. Since the facility accounts for approximately 30% of the City’s total electrical usage, energy efficiency measures can have a significant impact on plant operations and the City’s overall budget.

Overall, the project yielded a cost effective upgrade at minimal expense to the customer base while improving the efficiency and capacity of the plant and enabling multiple other benefits. In addition to the positive direct impacts to the City and the Sewer customers, this project simultaneously:

Removes HSOW from the watershed and thereby reduces nutrient loading to Lake Champlain, and the associated emissions from eutrophication.

Removes methane contribution to GHG emissions from the uncontrolled degradation of organics to the WRRF in a controlled process that captures that methane, thereby keeping those emissions out of the atmosphere.

Utilizes that methane as the energy source to offset nearly all of the WRRF's fossil fuel use.

Reduces the volume of waste that needs to be hauled to the Coventry landfill, thereby reducing the fossil fuel use to transport that waste.

Montpelier’s innovative wastewater treatment plant exemplifies the concept of the “urban biocycle” (the concept of capturing that material’s energy, nutrients, and other renewable resources and returning them to the community - a term coined by The Ellen MacArthur Foundation). The project advances a circular economy that by recovering and recirculating resources can ultimately replace waste with resilience.

“The WRRF Operators are committed to the City’s goal of Net Zero by 2030 and look forward to a Phase 2 project to utilize excess biogas. We are proud to work for a city so committed to environmental stewardship.”

Photos courtesy Energy Systems Group, LLC